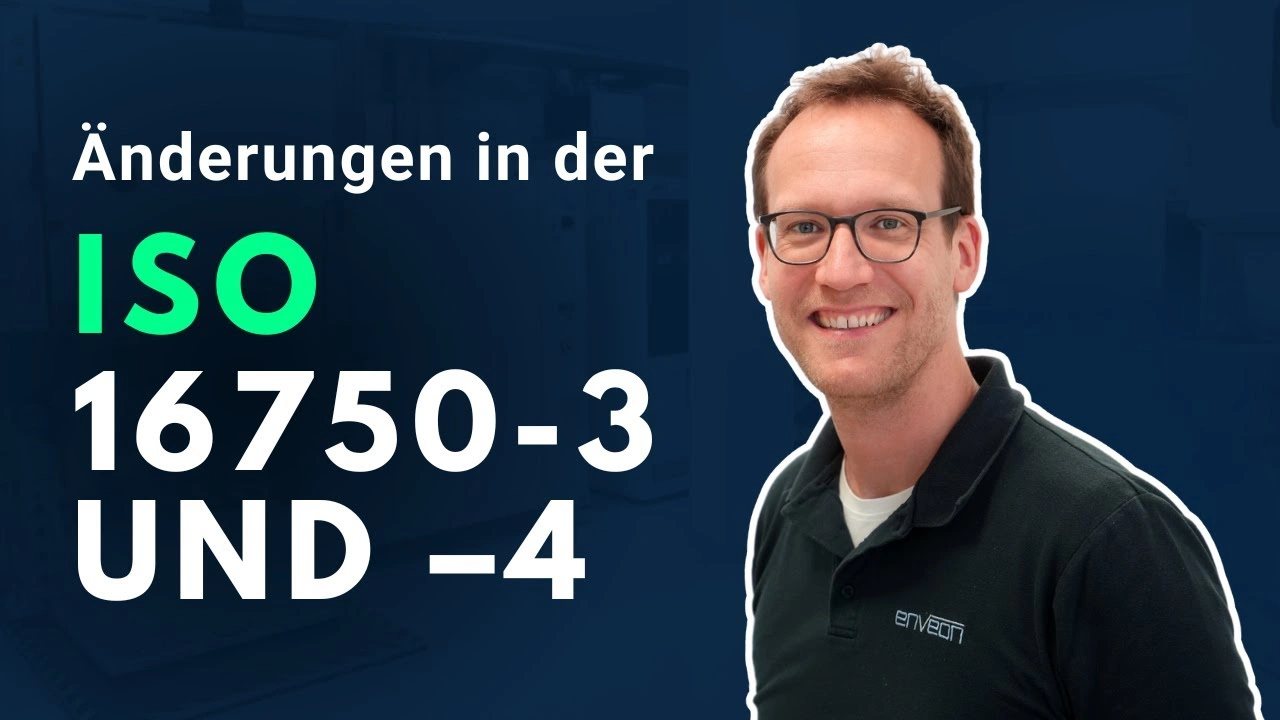

The new changes in ISO 16750-3 and -4: What does this mean for your vehicle electronics? Changes to ISO 16750-3 and 16750-4 , ISO 16750-3 and -4 are key standards for vehicle electronics. The latest edition of these standards introduces some significant changes that bring both opportunities and challenges for manufacturers and engineers. In this article, you will find out what adjustments have been made, how these could affect your testing processes and why the correct implementation is crucial to the success of your projects.

What kind of standard is ISO 16750?

ISO 16750 is a global standard that aims to ensure that electronic components in vehicles can withstand the often extreme environmental conditions. This standard is crucial to ensure the reliability and longevity of vehicle electronics, whether under extreme temperatures, vibrations or electrical loads.

The standard is divided into several parts:

- Part 1: General requirements.

- Part 2: Electrical tests.

- Part 3: Mechanical loads.

- Part 4: Climatic loads.

- Part 5: Chemical loads.

While Part 3 focuses on mechanical tests such as vibrations and shocks, Part 4 deals with electrical tests such as overvoltage tests and electromagnetic compatibility. Both parts are essential for the functional safety of vehicles, as failures in these areas can have serious consequences, ranging from malfunctions to safety-critical defects.

Overview of the changes in ISO 16750-4

The latest amendments to Part 4 of ISO 16750 relate in particular to the step temperature tests. These tests simulate critical temperature fluctuations to which electronic components are exposed in real use. A new addition is a more precise definition of the test conditions, which ensures that the temperature changes are now carried out under more realistic conditions.

Why is this important? Electronic components used in modern vehicles must be able to withstand extreme temperature differences without losing their functionality. The improved guidelines in ISO 16750-4 now provide an even more accurate assessment of this resilience and help to minimize the risk of failure in real-world applications.

Far-reaching adjustments in ISO 16750-3

Part 3 of the standard, which deals with mechanical loads, has undergone some far-reaching changes:

- Dynamic load profiles: One of the most significant changes concerns the introduction of more dynamic load profiles that are more specific to the different operating conditions of vehicles. Previously, all axles of a vehicle were treated equally in the vibration test. However, this led to unrealistic test conditions, as in practice each axle is subjected to different loads. The new standard now takes this into account by prescribing differentiated profiles for different vehicle parts and components.

- Extended test methods: New test methods have also been introduced that simulate a combination of vibrations and shocks under more realistic conditions. This is particularly important for components such as control units, batteries and connectors, which are exposed to both mechanical and thermal loads simultaneously during operation.

- High-frequency vibration tests: Another important innovation concerns the introduction of high-frequency vibration tests, which have been specially developed for testing lightweight, sensitive components. These tests help to ensure that even the smallest components, such as sensors and microcontrollers, can withstand the stresses in the vehicle.

Challenges and criticism

Increase in complexity: The new detailed regulations in ISO 16750-3 and -4 also increase the complexity of the test processes. The large number of new test profiles and the more precise definition of test conditions can lead to increased time and cost expenditure. Engineers have to deal more intensively with the specific requirements in order to select and adapt the right test profiles.

Need for adaptation to realistic tests: A frequent criticism of the new standards is that, despite their improvements, they do not always fully reflect the real operating conditions of a vehicle. Here it can be useful to develop customized tests that simulate specific load scenarios more accurately.

Training and further education: The introduction of new test procedures and increasing complexity also require continuous training and education for engineers. Without an in-depth understanding of the new standards, important details may be overlooked, which could lead to incomplete or incorrect testing.

Practical examples and implications for the industry

Battery testing: A practical example of the application of the new standards is the testing of battery modules in electric vehicles. These modules are particularly susceptible to mechanical stress caused by vibrations and shocks as well as extreme temperature fluctuations. The new standards allow these batteries to be tested under more realistic conditions, which increases the safety and longevity of the vehicles.

Testing of control units: Another example is the testing of control units, which are often exposed to high frequencies and electromagnetic interference. The new high-frequency vibration tests of ISO 16750-3 offer an improved methodology to ensure that these sensitive components can withstand the stresses of vehicle operation.

Why Enveon is the right partner for your audits

At Enveon, we specialize in compliance and implementation of standards such as ISO 16750. Our extensive equipment and in-depth expertise enable us to perform your testing accurately and reliably. We understand the challenges that come with the new changes and offer customized solutions to ensure your products meet the highest standards.

Our flexible resources and rapid response service, the Test Fire Brigade, enable us to respond to last-minute requirements and support your projects on time. Not only do we offer testing to the latest standards, but we can also create customized test profiles tailored to your specific requirements.

Get in touch with us

If you would like to find out more about the changes in ISO 16750 or need support in carrying out your tests, please do not hesitate to contact us. We are here to help you develop the right testing strategies for your products.